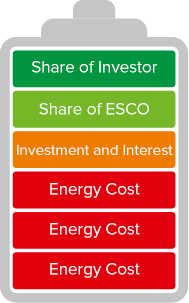

Kontek applies the ESCO business model for the factories and enterprises that want to reduce the energy costs thanks to the confidence based on its 25 years experience and technical background in the energy efficiency applications, while it undertakes all studies from analysis to projection also from implementation to the measurement, KONTEK serves financial solutions in addition to the turnkey&comprehensive engineering solutions. Providing energy efficiency services together with the expertise in the field of renewable energy and industrial automation under the single roof of a company, Kontek is a pioneer corporation that makes a big difference in the market.

Drives System Solution Provider with Expertise of AC Motor Control

GRID

TRANSFORMER

AC DRIVE

MOTOR

Applications

- Pump

- Fan

- Crusher

- Crane

- Chiller

- Compressor

- And Others...

Target

The main target is to reduce energy requirement via energy efficiency solutions and then to provide remain requirement via renewable energy.

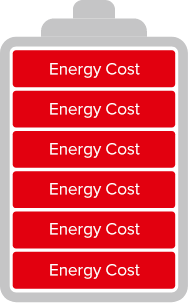

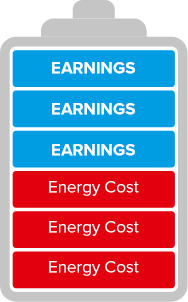

Why ESCO ?

- To reduce the energy costs without any investment costs and upgrade the comfort conditions!

- To make investments with the savings from energy efficiency solutions!

- To be influenced less from the energy cost increase!

- To bring a green world to the future increasing energy efficiency!

Energy Saving Performance Agreement

- Analysis

- Projection

- Measurement and Assessment

ESCO Phases

Pre-study

Our engineers visit the site and obtain information from the technical staff in your facility.

Letter of Intend

A letter of intent is signed by the investor that represents the request of investment assessment study to be done by Kontek.

Analysis & Projection

The devices to make energy efficiency are installed, measurement is undertaken and the analysis report is prepared accordingly. Then, an assessment of investment and financial feasibility is conducted.

Contract

Details regarding the design, construction, warranty, finance of the aforementioned project are clarified and an Energy Saving Agreement is signed.

Project Management and Application

Project studies are conducted and applications that will provide efficiency in the processes are completed.

Measurement and Correction

Energy saving amount is measured and reported, and the performance provided is verified.

Energy Efficiency in Different Sectors

Energy Efficiency in Processes

Energy Efficiency in Fans

Centrifugal Fans

Energy Efficiency in Compressors

Screw Compressors

Energy Efficiency in Pumps

Centrifugal Pumps